Load Factor Calculations

|

Load factor, in essence, means efficiency. It is the ratio of actual kilowatt-hours used in a given period, divided by the total possible kilowatt -hours that could have been used in the same period, at the peak kW level established by the customer during the billing period. A high load factor is “a good thing,” and a low load factor is a “bad thing.” A low load factor means that you are using electricity inefficiently relative to what you could be if you were controlling your peak demand. Load factor is calculated using a few simple numbers from the electric bill. The information required is:

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The ratio that the load factor formula expresses is the comparison between the actual kilowatt-hours used to the total possible kilowatt-hours that could be used at the particular kW level. | kWh | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

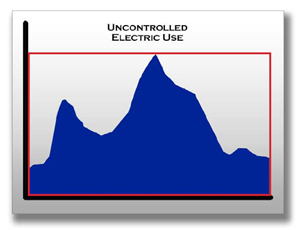

In the diagram to the right, the red box represents the total possible kilowatt-hours that could be used determined by the peak of electric use. The blue area represents the kilowatt-hours actually used over the month (daily profile shown to simplify drawing). The unshaded area represents the wasted capacity—the area where energy could have been used, but wasn’t. The point is that you paid for the capacity (demand) of the entire box (the demand charge), but didn’t use a large portion of it. Everything in the unshaded area is capacity you paid for but didn’t use. |  | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

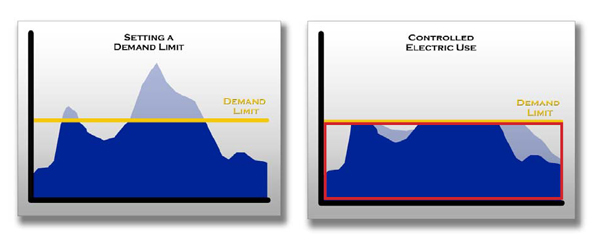

Conceptually, you can think of demand control as making the total size of the box smaller by decreasing the height. In the figures below, the yellow line is the demand limit or set point. By using an Energy Sentry demand controller, the peak demand is reduced by load management, and the original peak of energy use is redistributed below the limit. It’s not about changing how much electricity is used, but when it is used.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Using Load Factor to Determine Demand LimitTo determine a kW demand limit for a percentage load factor desired, take the actual kWh’s used by a home in a given month and divide by 720 (total hours in an average 30-day month):

If a 60% load factor is desired, take the 4.16 (100% load factor) and divide by .60.

If the kW peak is known and the kWh is known, load factor can be found by multiplying the kW by total hours, and dividing the actual kWh’s into that number. For example:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Recommended Maximum Demand Limits (Typical Residential Application)

Note: The demand limit may be higher or lower due to the individual lifestyle or to extreme variations in the weather. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Calculating Load Factor with Time-Of-Use RatesIf you are working with TOU rates, load factor must be calculated in a different way. Time-of-Use rates have separate On-Peak and Off-Peak times which must be calculated separately. The only changes here are:

If the Peak was different between On and Off-Peak times, use the appropriate Peak kW and use the basic load factor calculation above. If the TOU rate that you’re dealing with does not bill for demand in the Off-Peak periods, then calculating Off-Peak load factor is not necessary. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

ExampleLet’s suppose that you are in a situation where:

To calculate the On-Peak load factor, simply take the energy used during the On-Peak times and use the load factor calculation. Let’s say that a total of 4,000 kilowatt-hours were used during the billing period. We’ll assume that 15% or 600 kwh’s were used On-Peak with a demand of 8kW. The load factor is: 600 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Three notes of interest:

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Want to know more about Demand? Contact the experts at Brayden Automation Corp.