Control of Electric Furnaces

A homeowner can control the electric output of their electric furnances with the use of Energy Sentry demand controller. Please note: The following steps should be performed by a licensed electrician and is not recommended for homeowners.

Most residential furnaces have between 10 kW and 25 kW of resistance heat installed. Typically, the total wattage is divided into 5 kW elements, staged by timing relays controlled by a “sequencer.” The sequencer contains relays that turn on elements in stages. These relays allow some or all of the heat to come on, depending on the model or the controls. It is common to have 1st stage of 10kW; 2nd stage of 10kW and 3 stage (“emergency”) heat of 5kW.

The Energy Sentry demand controller can control the heat several ways depending on the number of elements and stages. Normally, those furnaces with 10kW or less are controlled via low voltage and those greater than 10kW can be controlled either in stages by disconnecting the low-voltage signals or by controlling each 5 kW element individually via line voltage.

Figure 1

Hook-up (Low-Voltage Control – Single Stage)

- Refer to the diagram on the furnace and locate the sequencing relays for the heating elements and determine the number of stages. This is normally the same as the number of heat relays in the furnace.

- For a 10kW furnace or less, control the heat by breaking the white wire (W or W1) which runs between the thermostat and the electric furnace as shown in Figure 1.

- Run a 2-conductor, #18-gauge wire from the demand control unit to the low voltage control compartment of the furnace. Run the coil voltage of the pilot relay back to the demand controller and connect to the desired relay output.

- Interrupt the heat control wire W or W1 before the sequencer in the furnace. Upon the opening of the normally closed pilot relay in the heat circuit, the sequencer will interpret this as a “satisfied” condition and being turning off the elements.

- The only negative aspect in doing control in this matter is the time delay that occurs before all of the heat is turned off. This is the single biggest reason that this method yields poor control performance in furnaces with more than 10kW of heat. Of course, if your averaging period is 30 or 60 minutes, this is less of a problem.

Hook-up (Low-Voltage Control – Multiple Stage)

- Refer to the diagram on the furnace and locate the sequencing relays for the heating elements and determine the number of stages. This is normally the same as the number of heat relays in the furnace.

- For furnaces of 15kW to 25kW, control can be adequately achieved by controlling the heat relay stages as shown in Figure 2. Normally there are two 5kW elements per stage so your minimum demand limit will have to be greater than the sum of the two elements on this stage, or 10kW in this example. While this works better than controlling the all of the heat with only the W (Heat) control wire, it works best for 30 or 60-minute demand averaging interval areas. You may experience problems in 15 minute averaging areas. If you have 20kW to 25kW of heat, it is recommended that you control the elements individually. Superior control can be achieved in this manner. See section 3 of this Tech Tip.

- Run a control cable with 2- #18 gauge conductors for each stage that will be controlled. For example, you have 25kW in 3 stages so you will need 3 pilot relays. Each pilot relay requires two #18-gauge wires from the demand control unit. Run a 6-conductor cable between the demand controller and the low voltage control compartment of the furnace. Connect the coil wires of each pilot relay to the demand controller’s desired relay output.

- Interrupt the non-common side of each heat relay’s coil with a normally-closed pilot relay as shown in Figure 2. Upon the opening of the normally-closed pilot relay in the heat circuit, each stage will turn off the elements immediately.

- This will derive satisfactory results with the only negative aspect of doing control in this matter is that you must set your minimum demand limit AT LEAST one or two kW higher than the highest sum of heat circuits on any relay for the heating season.

- With electric furnaces, the load control strategy should be programmed as “fixed priority,” in the same order as the loads are controlled by the sequencer. Refer to Tech Tip #13 for information about load control strategy.

Individual Element Control

This method of control yields superior results on those furnaces with 15kW to 25 kW of heat. This is because you are dividing a large load down into smaller (5kW in most cases) blocks of demand and it makes it much easier to control and to maintain comfort in the home.

Figure 3

- Turn breaker OFF at the furnace. This normally consists of at least two double-pole breakers. Be careful to insure that ALL power to the electric furnace is off.

- If a Remote Relay Unit is required, mount it in a suitable place on or near the furnace housing. If the furnace is close enough to run conduit or flex between the main control unit and the furnace, make the connections directly at the control unit itself.

- Interrupt the 10-gauge wires that feed each element and rewire them through the relays as shown in Figure 3 above. Use one element per relay if possible (four or five elements typical). Use two elements per relay if necessary (five or six elements typical).

- Follow the directions that come with the Remote Relay Unit to hook it to the main control unit. See the Tech Tip on Remote Relay Units for more information.

- With electric furnaces, the load control strategy should be programmed as “fixed priority,” in the same order as the loads are controlled by the sequencer. Refer to Tech Tip #13 for more information on load control strategy.

Caution

Because most sequencing relays have built-in time delays of an unknown length, it is best to use the “individual element” control method, if possible, for superior control results.

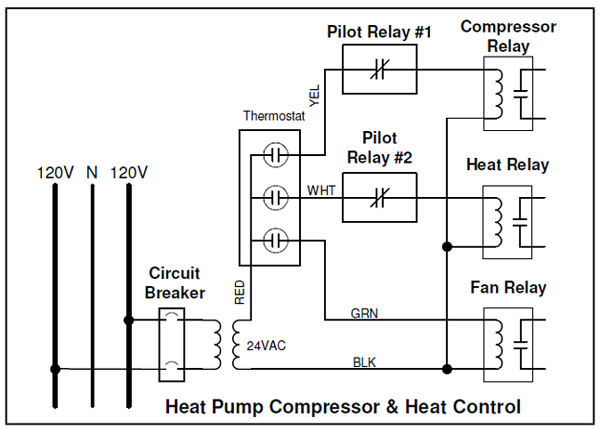

Control of Heat Pumps: Examples of Priority Hook-ups

| 4-Relay Models Models (Control of Heat- Low Voltage) | ||||

|---|---|---|---|---|

| Last Shed | 24-hour control | First Shed | ||

| Relay | 1 | 2 | 3 | 4 |

| Load | Dryer | Water Heater | 10kW Heat | 10kW Heat |

| 8-Relay Model or 4-Relay Model with 4-Relay Remote Relay Unit Auxiliary Heat Individual Elements- Line Voltage Control | ||||||||

|---|---|---|---|---|---|---|---|---|

| Last Shed | 24-hour control | First Shed | ||||||

| Relay | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Load A | Dryer | Water Heater | 5kW Heat | 5kW Heat | 5kW Heat | 5kW Heat | 5kW Heat | 5kW Heat |

| To Remote Relay Unit | ||||||||

| 20kW Furnaces | ||||||||

Caution

In extremely cold regions, it may be necessary to leave the first 5kW element uncontrolled to avoid having the blower run with all the elements turned off. Another alternative is to connect the first 5kW element to the highest priority control point, thereby making it the last shed. Contact Brayden Automation for assistance on connecting the electric furnace to the demand controller.