Control of Electric Clothes Dryers

Most electric clothes dryers used in homes today have 5500-watt , 240-volt heating coils with a 120-volt fractional horsepower motor. It is very difficult to operate an all-electric home below 8 kW if the dryer is not controlled by a demand controller. To properly connect a dryer to an Energy Sentry®, follow the procedure below. This should be done by a licensed electrician and is not recommended for homeowners.

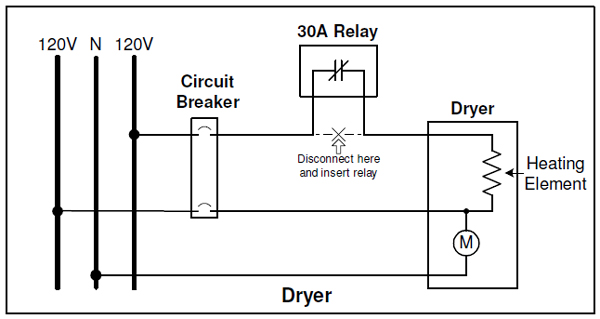

Figure 1

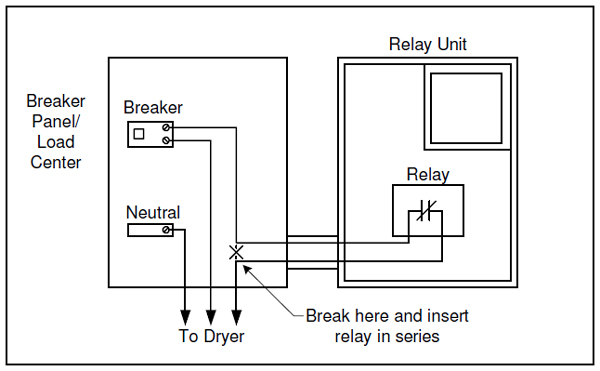

Figure 2

Hook-up

- Turn dryer breaker OFF.

- Disconnect one wire from the Dryer’s double-pole breaker and cap or insulate wire.

- Turn dryer Breaker ON.

- Turn dryer ON. If dryer operates (starts), you have disconnected the heating coil wire. This is the correct wire for control. Go to Step #5. If the dryer does not start, the connected wire is the heating coil wire and the disconnected wire is the motor wire. Turn dryer breaker OFF. Reconnect the motor wire to its original position on the breaker and disconnect the opposite wire – the heating coil wire. Do the test again to insure that dryer starts with the heating wire disconnected.

- Turn dryer breaker OFF (or insure that it is already OFF). Connect the heating coil wire to the Energy Sentry relay as shown in the figures above. When finished, turn the dryer breaker ON.

- Make a note on Dryer Breaker in Breaker Panel that the Dryer is controlled by the Energy Sentry Demand Control System.

Warnings

- Beware of mislabeling. Make sure the 30-amp breaker is the dryer’s breaker and not the water heater’s breaker. (the other 30-amp breaker common in most breaker panels)

- Only the heating coil leg of the dryer circuit should be connected to the demand controller. Connecting the motor leg can overheat and damage the dryer motor. If the dryer is not in place (i.e. if you are installing in an unoccupied home), the dryer circuit should not be connected to the controller at this time.

- If any loads connected to the Energy Sentry demand control system are wired with aluminum wiring, insure that connections between existing aluminum conductors and copper conductors of the Energy Sentry are properly done using a Copair tool, anti-oxident paste or anti-oxident impregnated wirenuts.

Quick Test

- Lower demand limit to minimum setting. Turn ON oven and range until all controlled loads are shed. This may take a few minutes. Press Dryer Start button. Dryer’s motor should start.

- Turn OFF oven and range.

- Restore demand limit to normal level.

Note

Dryer manufacturers have not standardized to which leg they attach the motor. You have a 50% chance that it will be right. If you purchase a new dryer, or you move into a home with a demand controller already installed, there is no guarantee that the dryer will be wired the same as your existing dryer(or previous dryer in the home). If your new dryer stops or exhibits unusual behavior, the new dryer may be wired incorrectly to the demand controller. Have your electrician switch (swap) the phases on the dryer cord at the back of the dryer. It is easiest to change it here instead of changing the dryer plug or wiring at the demand controller and breaker panel. Contact Brayden Automation Corporation or your local dealer if you need assistance on resolving this problem.